In Figeac, a village founded in medieval times, a modern aircraft propeller factory sits in quiet harmony in one of the most beautiful landscapes in France.

If you visit, you can walk the cobblestoned streets past houses built in the 12th century. Or you can enjoy hikes and bicycle rides in the Lot Department where pristine rivers, lakes and forests invite you to enjoy some of the cleanest air in France.

Aircraft propellers have been manufactured here for more than a century starting with props for the aviation pioneers and then the French Air Force aircraft during World War 1. The production started here by Paulin Ratier because of the beech wood found in forests nearby. This wood has desirable qualities for propellers including consistent texture and impact resistance.

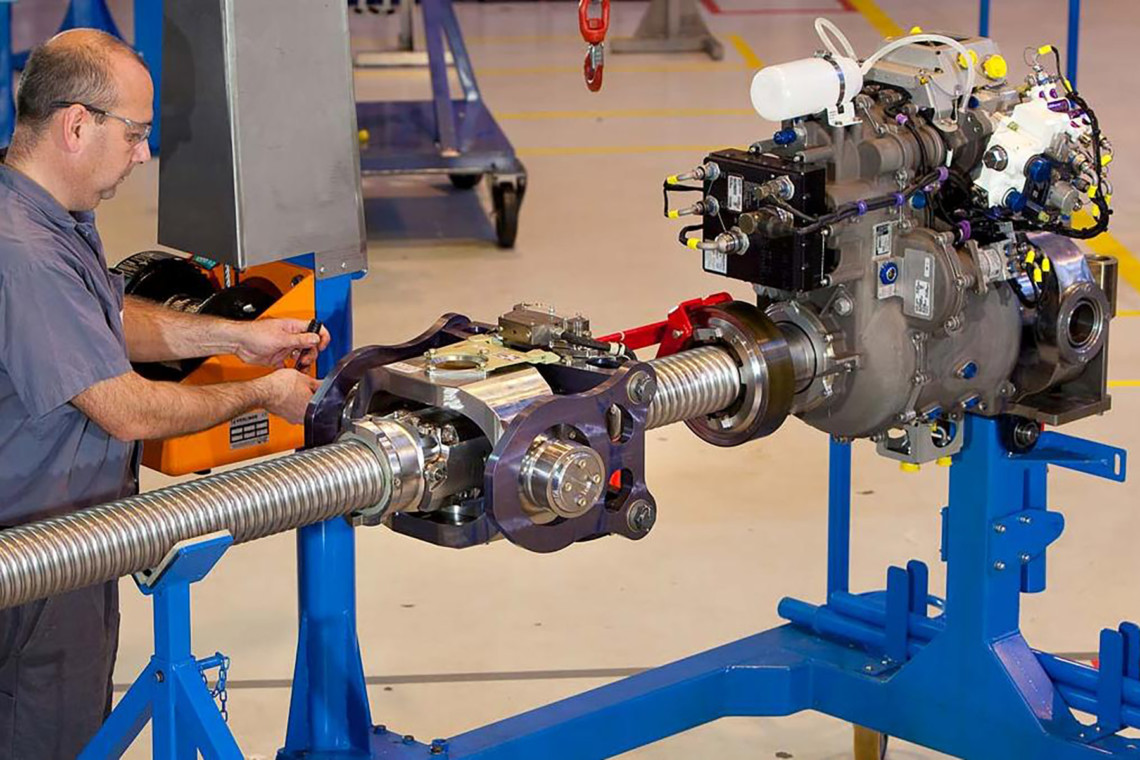

Today, propellers for high performance military transport aircraft and regional airlines are made of composite material including graphite and Kevlar. Ratier-Figeac, a unit of Collins Aerospace, works to keep its factory activity compatible with the local environment while designing aviation products and services that produce fewer greenhouse gas emissions.

When the company decided to expand its research, development and testing capability at its 53,000 square meter plant in Figeac, workers at the factory came up with an energy saving idea. They suggested that the 2,300 square meter addition be heated by capturing the heat generated by industrial processes in the main plant. Jean-Francois Chanut, General Manager of Propeller Systems at Collins Aerospace and president of Ratier-Figeac, said this thinking shows how the 1,200 employees take their role in protecting the environment seriously.

The 10,000 people who live in Figeac are interested in the propeller business and visit the propeller museum which tells the full story. ‘We have been here in Figeac for 100 years and people want to make sure we’re going to be here for another 100 years,’ said Chanut. During his 25-year career in aerospace, serving in a variety of management and engineering roles, he has worked with the most demanding customers such as the Airbus Group, Dassault and Boeing.

The aerospace industry worldwide is taking the initiative to reduce its carbon footprint across the board and Collins Aerospace has been working on these issues for several decades. During the past decade in Figeac, the company reduced its overall greenhouse gas emissions by 45% while business activity rose 50%.

Phill Godfrey, director of international strategy in Europe for Collins Aerospace, outlines the company’s three-pronged green strategy for all its business units. It has three goals:

- Stakeholder Engagement – collaborating with business partners, employees and communities to identify and progress priorities for sustainable aviation

- Technology Roadmap – developing solutions on aircraft and at airports to reduce greenhouse gas emissions with individual products and integrated systems

- Industrial Roadmap – reducing carbon footprint whenever possible in Collins Aerospace operations and in the company’s supply chain.

Godfrey said these goals fit hand in glove with the European Union’s Green Deal. He has worked for three other major aerospace companies with challenging environmental objectives before joining Collins Aerospace and holds degrees in physics and manufacturing. This background helped prepare him to formulate strategies to help customers tackle some of their toughest environmental challenges.

Ratier-Figeac is in the enviable position of already working in a product area which has one of the lowest carbon footprints in commercial and military aviation.

Turboprop aircraft, powered by engines driving propellers, burn 30 to 40 percent less fuel than the equivalent jet-powered aircraft. ‘Our customers operate aircraft that perform better in terms of performance, fuel consumption and emission of greenhouse gasses,’ said Chanut.

The company has been engaged in an aggressive research and development programme since 2016 to advance the state of the art in its line of high-performance propellers. The initiative comes at a time when the world of civil aviation is moving away from its heavy dependence on kerosene-based jet fuel. Turboprop engines can burn sustainable aviation fuel (SAF) or hydrogen in the future and these engines may be replaced with electric engines or hybrid systems that use both fuel and electricity at times. Regardless of what power source is used, Ratier-Figeac will provide the best optimised propellers.

The advantage of hydrogen and electricity is that they do not produce greenhouse gas emissions.

Ratier-Figeac aims to design new propellers using new technologies and materials that will weigh less and have more efficient aerodynamic properties while producing less noise and emissions. This type of advanced design propeller will help airplanes use less fuel, electricity or hydrogen to operate. Communities and airports will enjoy the reduced noise profile and passengers will enjoy a more comfortable ride with less vibration.

‘We aim at leading the way in improving our environmental footprint both from a product standpoint with our advanced propellers used around the world and from an industrial standpoint here in Figeac,’ concluded Chanut.